|

|

Nigel's Remote Tester.

The

first stage of this project was deciding on a suitable case, after much

studying I found one in RS Components which is ideal, it has an IR

transparent front available, and includes a space for a 9 volt battery. I

needed a low profile switch for the power, and again a suitable one was

found in the RS Components catalogue. The

first stage of this project was deciding on a suitable case, after much

studying I found one in RS Components which is ideal, it has an IR

transparent front available, and includes a space for a 9 volt battery. I

needed a low profile switch for the power, and again a suitable one was

found in the RS Components catalogue.

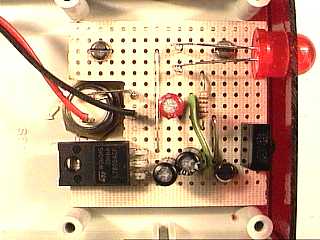

The

circuit itself is nice and simple, I used components I had to hand, and

selected an IR detector from a Tatung D Series TV for the actual sensor,

with a 7805 IC regulator providing the supply - a 78L05 would be ample,

but I had the 7805 in stock. If you want to use a 78L05, you are welcome

to do so!. The

circuit itself is nice and simple, I used components I had to hand, and

selected an IR detector from a Tatung D Series TV for the actual sensor,

with a 7805 IC regulator providing the supply - a 78L05 would be ample,

but I had the 7805 in stock. If you want to use a 78L05, you are welcome

to do so!.

You can get the RS Components parts from their website at http://rswww.com

- they accept orders from non-account holders, but you have to pay

postage, account holders get free postage.

|

Parts List

|

Case |

RS 262-6474 |

|

IR Panel |

RS 262-6496 |

|

Switch |

RS 321-256 |

| REG1 |

LM7805CT |

| LED |

RS 590-171 |

| C1 |

1uF 16v |

| C2 |

1uF 16v |

| C3 |

47uF 16v |

| R1 |

270ohm |

| IR Det. |

Tatung D Series

TFMS5360 |

| Batt. Lead |

RS 489-021 |

|

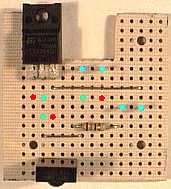

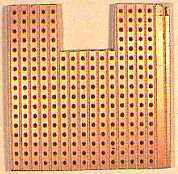

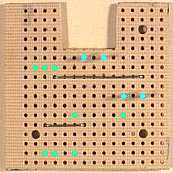

First

part of building the tester is to cut the Veroboard to size, it needs a

piece 15 strips by 17 holes, and no breaks in the copper strips are

required. A small piece 6 strips by 5 holes requires removing at one

end, this is to provide clearance for the push button switch, the picture

shows this nice and clearly. First

part of building the tester is to cut the Veroboard to size, it needs a

piece 15 strips by 17 holes, and no breaks in the copper strips are

required. A small piece 6 strips by 5 holes requires removing at one

end, this is to provide clearance for the push button switch, the picture

shows this nice and clearly. |

|

|

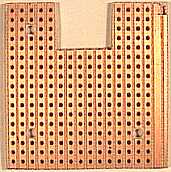

Next

drill the three mounting holes in the board, for these I used a 3/32"

drill, to give a suitable clearance for the screws used to fasten the

board. Next

drill the three mounting holes in the board, for these I used a 3/32"

drill, to give a suitable clearance for the screws used to fasten the

board.

|

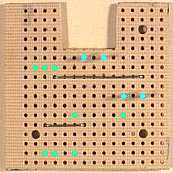

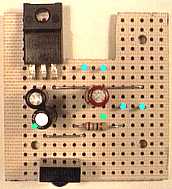

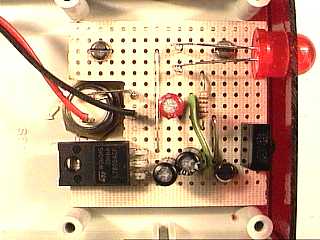

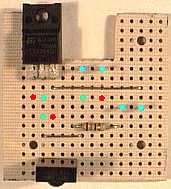

Now

it's time to start assembling the board, start by adding the two wire

links, and four Vero pins. The Vero pin locations are shown by the light

blue circles, the light green circles show the holes for the components in

the next step. Now

it's time to start assembling the board, start by adding the two wire

links, and four Vero pins. The Vero pin locations are shown by the light

blue circles, the light green circles show the holes for the components in

the next step. |

|

|

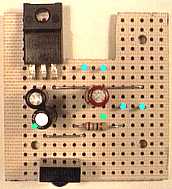

Now

it's time to mount the first components, the 7805 regulator, the 270 ohm

resistor, and the IR detector, these fit in the holes marked light green

in the previous picture. As before the light blue circles signify the Vero

pins, and the light green (and red this time) circles show where the next

components fit - with the red circles being the positive connection of the

capacitors. Now

it's time to mount the first components, the 7805 regulator, the 270 ohm

resistor, and the IR detector, these fit in the holes marked light green

in the previous picture. As before the light blue circles signify the Vero

pins, and the light green (and red this time) circles show where the next

components fit - with the red circles being the positive connection of the

capacitors.

|

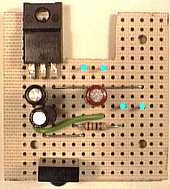

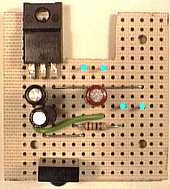

This

shows the board with the three capacitors fitted, the two close together

at the left are the 1uF, the one on it's own in the middle of the board is

the 47uF. This time the two green dots show the location of an insulated

wire link. This

shows the board with the three capacitors fitted, the two close together

at the left are the 1uF, the one on it's own in the middle of the board is

the 47uF. This time the two green dots show the location of an insulated

wire link. |

|

|

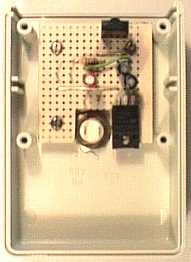

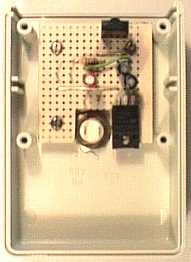

This

is now the finished board, it only requires fitting in the case with three

M2 screws. This

is now the finished board, it only requires fitting in the case with three

M2 screws.

|

Now

it's time to start work on the case, first mark the center of the top, and

drill a half inch hole. You then need to file the hole out until the

switch fits, it has a flange which is larger than the threads, this needs

to fit in the hole. Make sure the switch fits nice and flush. Now

it's time to start work on the case, first mark the center of the top, and

drill a half inch hole. You then need to file the hole out until the

switch fits, it has a flange which is larger than the threads, this needs

to fit in the hole. Make sure the switch fits nice and flush. |

|

|

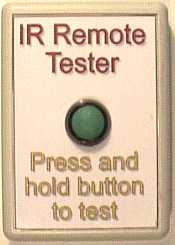

Next

stick the front label on, this was designed using Microsoft Publisher

2000, and printed on thin card. This was then laminated and cut out,

laminating provides a nice tough shiny finish, and makes the project look

really professional. I used Super Glue to fasten the label on, although

I've never liked Super Glue it works superbly for this application. You

can download the label as a PDF file, and then print it out, make sure you

have it set to print at 100% to make sure it's the correct size - or feel

free to make your own label. Next

stick the front label on, this was designed using Microsoft Publisher

2000, and printed on thin card. This was then laminated and cut out,

laminating provides a nice tough shiny finish, and makes the project look

really professional. I used Super Glue to fasten the label on, although

I've never liked Super Glue it works superbly for this application. You

can download the label as a PDF file, and then print it out, make sure you

have it set to print at 100% to make sure it's the correct size - or feel

free to make your own label.

|

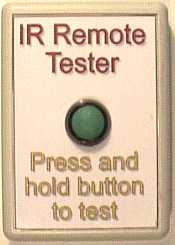

The

next operation is cutting the front label for the switch, this is easily

done using a sharp knife, just cut a cross through the hole, and then cut

around the hole. Once the hole is clear, mount the switch and tighten the

nut, making sure the terminals are aligned horizontally. The

next operation is cutting the front label for the switch, this is easily

done using a sharp knife, just cut a cross through the hole, and then cut

around the hole. Once the hole is clear, mount the switch and tighten the

nut, making sure the terminals are aligned horizontally. |

|

|

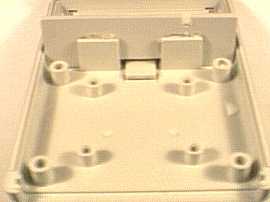

Then

mount the board to the underneath of the top, it's fastened with three

short M2 screws (one hole is obstructed by the 7805), if you have self-tappers

use those, but I found normal threaded screws work perfectly

satisfactorily. Then

mount the board to the underneath of the top, it's fastened with three

short M2 screws (one hole is obstructed by the 7805), if you have self-tappers

use those, but I found normal threaded screws work perfectly

satisfactorily.

|

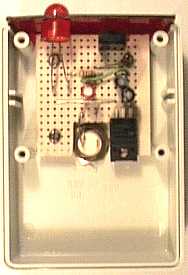

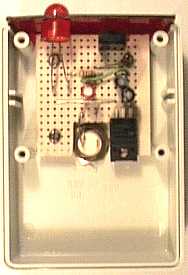

Now

it's time to mount the LED, first you need to carefully drill a 3/8"

hole in the IR panel 17mm in and 8mm down - be careful, it's quite brittle

and easily broken. Then carefully file this out until the LED is a tight

fit, it doesn't matter if it's a bit loose, we'll secure it with hot melt

glue later. Push the LED into the hole with the long wire towards the left

(looking at the picture), slide the IR panel into the front slot, and bend

the wires down to the two Vero pins, cutting them as required. Then solder

the wires to the pins, a short length of copper wire is also soldered from

the left hand switch connection to the left hand Vero pin at the lower

middle of the board. Now

it's time to mount the LED, first you need to carefully drill a 3/8"

hole in the IR panel 17mm in and 8mm down - be careful, it's quite brittle

and easily broken. Then carefully file this out until the LED is a tight

fit, it doesn't matter if it's a bit loose, we'll secure it with hot melt

glue later. Push the LED into the hole with the long wire towards the left

(looking at the picture), slide the IR panel into the front slot, and bend

the wires down to the two Vero pins, cutting them as required. Then solder

the wires to the pins, a short length of copper wire is also soldered from

the left hand switch connection to the left hand Vero pin at the lower

middle of the board. |

|

|

The

last electrical operation is to solder the battery connector to the switch

and board. It can be clearly seen here, the red wire goes to the switch

and the black wire to the remaining Vero pin. Tie a knot in the lead about

2 inches from the battery connector, this acts as a flex grip and prevents

the wires being pulled off. The

last electrical operation is to solder the battery connector to the switch

and board. It can be clearly seen here, the red wire goes to the switch

and the black wire to the remaining Vero pin. Tie a knot in the lead about

2 inches from the battery connector, this acts as a flex grip and prevents

the wires being pulled off.

|

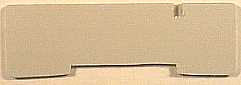

With

the top of the unit all completed, it's time to start on the bottom part.

First we will use the original front to make a better compartment for the

battery, and give somewhere for the flex grip knot to sit. Cut a long thin

rectangle from the middle of one long edge, this is to clear the latch

from the battery cover, it's also beneficial to taper this edge slightly,

this is also to help clear the latch. Next trim the opposite edge about

1/8 inch, this is to allow the partition to fit inside the case, adjust it

as required. At this side cut a small slot, this is for the battery wires,

it should be small enough for the knot to prevent the wires pulling

through. With

the top of the unit all completed, it's time to start on the bottom part.

First we will use the original front to make a better compartment for the

battery, and give somewhere for the flex grip knot to sit. Cut a long thin

rectangle from the middle of one long edge, this is to clear the latch

from the battery cover, it's also beneficial to taper this edge slightly,

this is also to help clear the latch. Next trim the opposite edge about

1/8 inch, this is to allow the partition to fit inside the case, adjust it

as required. At this side cut a small slot, this is for the battery wires,

it should be small enough for the knot to prevent the wires pulling

through. |

|

|

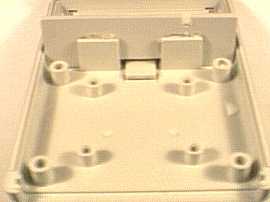

Now

using hot melt glue, fasten the partition to the two small existing

partitions, as you can see in the picture the battery flap latch comes through

the portion removed from the partition, and the slot for the battery wires

can be seen at the upper right. Now

using hot melt glue, fasten the partition to the two small existing

partitions, as you can see in the picture the battery flap latch comes through

the portion removed from the partition, and the slot for the battery wires

can be seen at the upper right.

|

While

the glue gun is still hot, stick a piece of thin foam rubber in the bottom

of the battery compartment - to stop it rattling. Then use a dab of hot

melt glue to secure the LED to the front panel. The unit is then

completed, and you can screw the bottom on, taking care to feed the

battery wire through the slot, with the knot on the inside. While

the glue gun is still hot, stick a piece of thin foam rubber in the bottom

of the battery compartment - to stop it rattling. Then use a dab of hot

melt glue to secure the LED to the front panel. The unit is then

completed, and you can screw the bottom on, taking care to feed the

battery wire through the slot, with the knot on the inside. |

|

|

![]() The

first stage of this project was deciding on a suitable case, after much

studying I found one in RS Components which is ideal, it has an IR

transparent front available, and includes a space for a 9 volt battery. I

needed a low profile switch for the power, and again a suitable one was

found in the RS Components catalogue.

The

first stage of this project was deciding on a suitable case, after much

studying I found one in RS Components which is ideal, it has an IR

transparent front available, and includes a space for a 9 volt battery. I

needed a low profile switch for the power, and again a suitable one was

found in the RS Components catalogue.